Kurkure Making Machine Manufacturer

Gulab Singh & Co. is an ISO-certified manufacturing firm based in India, known for delivering innovative, reliable, and efficient food processing machinery. As a leading kurkure making machine manufacturer, we are dedicated to designing and producing high-performance machines that cater to the growing needs of the snack industry.

In the rapidly evolving world of snacks and food processed manufacturing, Kurkure has established itself as a top favorite among consumers across India and around the globe. Behind the irresistible crunch and flavor of Kurkure lies a powerful and precision-driven process — and at the heart of that process is the Kurkure making machine. One name that has earned trust, reputation, and industry-wide recognition in manufacturing high-quality Kurkure production machinery is Gulab Singh & Company.

Gulab Singh & Company is a leading Kurkure making machine manufacturer in India , catering to the growing demand for automated, high-performance snack processing equipment. Whether you are a startup in the snack food industry or a large-scale food processing plant, Gulab Singh & Co provides tailor-made solutions designed to boost your productivity and deliver consistent results.

Our Products

Types of Kurkure Making Machines – A Complete Guide

Kurkure is one of the most popular and high-demand snacks in India and several international markets. As consumer appetite for crunchy, flavorful snacks continues to rise, entrepreneurs and manufacturers are increasingly investing in kurkure making machines. But with multiple machine types available, how do you choose the right one?

This complete guide will walk you through the various types of kurkure making machines based on automation level, production capacity, and components involved in the complete production line.

Fully Automatic Kurkure Making Machine – These machines automate the entire kurkure production process — from mixing and extruding to frying/roasting, flavoring, and packaging. Large-scale snack factories and commercial plants.

Semi-Automatic Kurkure Making Machine – Core processes like extrusion and frying are machine-operated, but steps like feeding raw materials and collecting output may require manual effort. Medium-sized manufacturers or growing businesses.

Mini Kurkure Making Machine – Compact and budget-friendly machines, ideal for startups or local production units. Small businesses, test batches, and cottage industries.

Kurkure Making Machines: What We Offer

Gulab Singh & Co, we offer a complete range of Kurkure making machines – from raw material processing to extrusion, cutting, frying, flavoring, and packaging. Each machine is constructed using high-grade materials and tested against strict quality parameters.

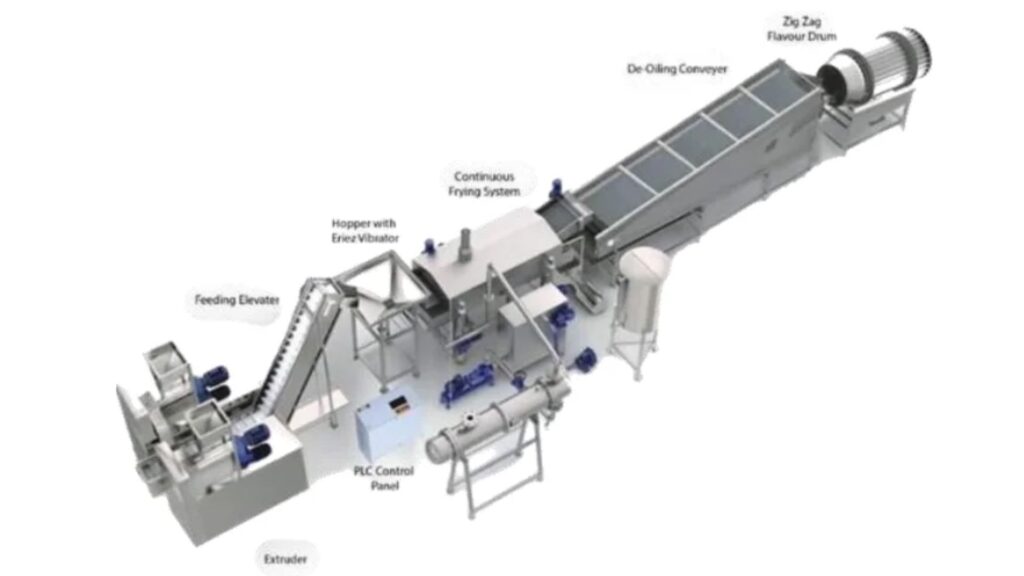

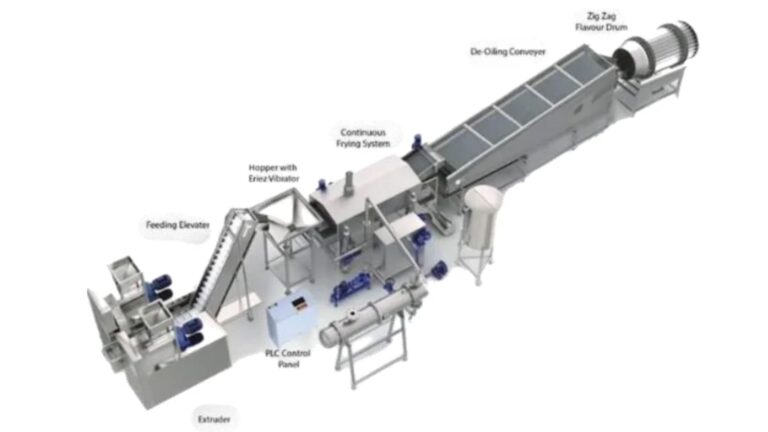

Here a breakdown of the key components of our Kurkure production line:

Kurkure Extruder Machine – The core of any Kurkure production unit is the extruder. Our Kurkure extruder machine uses corn grits as the main raw material. The extruder processes these grits through heat and pressure, creating the iconic spiral shape of Kurkure. Our extruders are made with heavy-duty stainless steel, have advanced temperature control systems, and high-efficiency gearboxes, ensuring superior performance and product uniformity.

Cutting & Feeding Unit – After extrusion, the dough is cut into Kurkure-sized pieces with a rotating cutter. Our machines ensure that every piece is cut evenly, improving final product consistency. The feeding unit conveys these pieces smoothly to the next stage without breaking or damaging them.

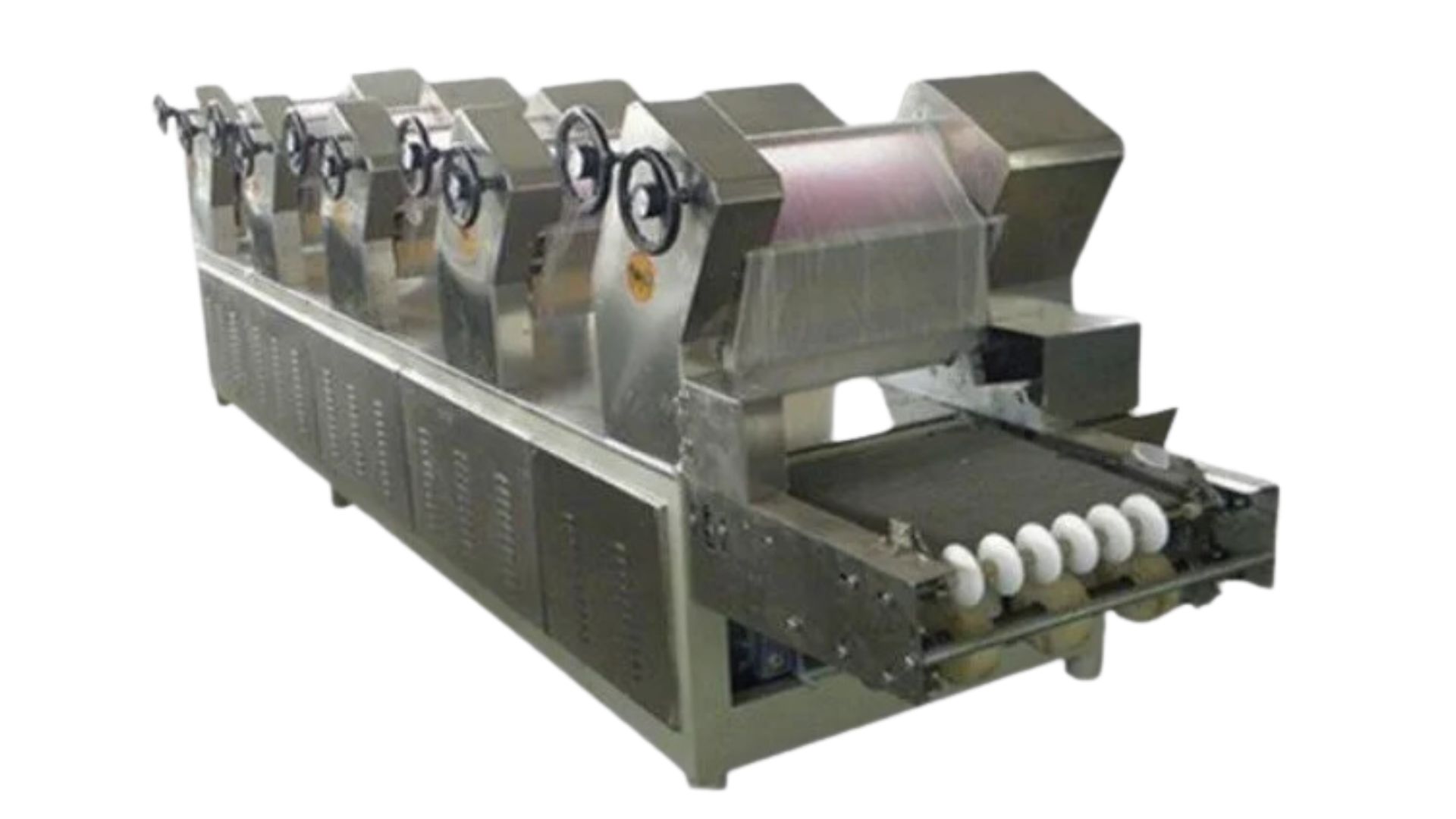

Kurkure Frying Machine – The frying unit is a critical part of the process. We offer batch-type and continuous frying systems, designed to provide even and oil-efficient frying of Kurkure pieces. These machines are built with thermostat controls, oil filtration systems, and are easy to clean, making them ideal for hygienic and efficient operations.

Flavoring & Seasoning Machine – Kurkure gets its final delicious taste from the flavoring process. Our seasoning machines are fitted with rotary drums and spray systems that coat the Kurkure uniformly with spices, herbs, and seasonings. The machine ensures minimum wastage of masala while maintaining a consistent taste across the batch.

Kurkure Packing Machine – To ensure long shelf life and market-ready products, we provide automatic Kurkure packing machines compatible with various pouch sizes and styles. These packing systems offer air-tight sealing, high-speed operation, and integration with weighing scales and date printers.

Key Features of Our Kurkure Making Machines

Stainless Steel Construction for long-lasting performance and hygiene

Energy-efficient motors to reduce power consumption

High automation to reduce manpower needs

Modular design for easy upgrades or maintenance

Customizable output capacity (from 100kg/hr to 500kg/hr and more)

PLC-based controls for precision and ease of use

Why Choose Gulab Singh & Co. for Kurkure Making Machine?

When it comes to quality, innovation, and reliability in the snack food machinery industry, Gulab Singh & Co. stands out as one of India’s most trusted Kurkure making machine manufacturers. With decades of experience and a strong commitment to customer satisfaction, we provide end-to-end solutions for Kurkure production lines—customized to meet the needs of every scale, from startups to large-scale industries.

industry-Leading Experience – We bring years of hands-on expertise in designing and manufacturing a wide range of snack food processing machines. Our deep understanding of the food processing industry ensures that you get machinery that meets real-world demands with precision and reliability.

Robust Machine Build & Latest Technology- Our Kurkure machines are built using high-grade stainless steel, advanced rotary die technology, and energy-efficient systems. Whether you choose a mini machine or a fully automatic line

Customized Solutions for Every Business Size – We offer machines in various capacities (25 kg/hr to 500+ kg/hr), automation levels (manual, semi, and fully automatic), and layouts to suit your space, budget, and scale of production. We can also help design your full Kurkure plant for optimal workflow and efficiency.

Complete Production Line Support – From mixing and extrusion to frying, seasoning, and packaging—we provide complete Kurkure production line solutions under one roof. No need to coordinate with multiple vendors.

Competitive Pricing with No Quality Compromise – We maintain affordable pricing to support startups and growing businesses, without compromising on quality or performance. Our machines deliver long-term ROI through low power consumption, high efficiency, and minimal downtime.

Nationwide & International Reach – With satisfied clients across India and overseas, we export Kurkure machines that comply with international standards. Wherever your business is located, our team ensures timely delivery, safe installation, and reliable after-sales support.

Excellent After-Sales Service – We believe in building relationships, not just selling machines. Our responsive after-sales service includes:

Trusted by Hundreds of Snack Brands – From small snack startups to well-known FMCG players, hundreds of clients trust Gulab Singh & Co. for their Kurkure machine needs. Our reputation is built on quality machines, honest pricing, and dependable service.

If you’re looking to enter the snack food market or expand your current production line, investing in a Kurkure making machine from Gulab Singh & Company is the right choice. We combine technological innovation, superior build quality, and customer-first values to help you succeed in a competitive industry.