Kurkure Production line Manufacturers

Gulab Singh and Co. is a reputable kurkure production line manufacturers and suppliers of kurkure making machine, and kurkure plant in India. Our skilled professionals construct the production line we’re offering using premium materials and cutting-edge technology according to standards set by the industry. In addition, our provided production line is put through various inspections by our quality experts to guarantee its quality.

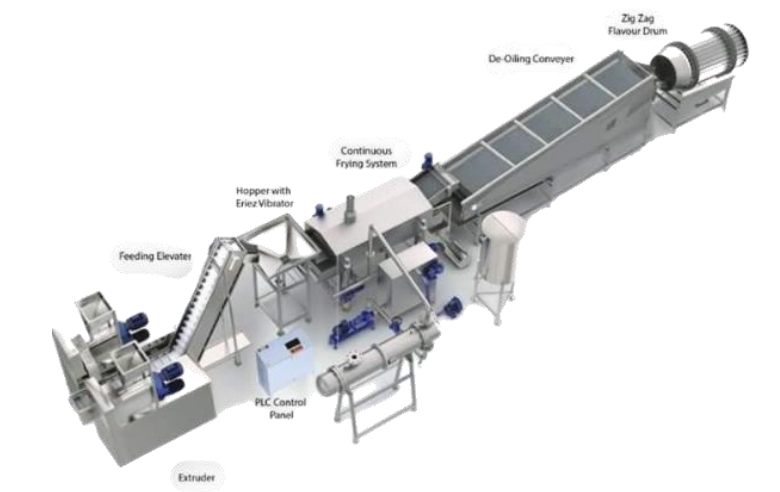

Features

- Grit Mixer and Cum Feeder

- Extruder

- Feeding Elevator

- Rotary Sever

- De-oiling Belt

- Flavor Applicator & Drum

- Control Panel

Kurkure Production Line is a spicy snack that people can enjoy during tea time, and this completely automated, fully automatic kurkure making machine is utilized to make them. This production line, which we at Gulab Singh and Co. offer, is fully made of stainless steel and is renowned for its attributes such as simplicity of cleaning, trouble-free assembly, adaptable regulating technology, and high automation level. This production line’s ergonomic design encourages quick and extremely efficient production. This kurkure production line is made up of various pieces of machinery and systems. The snack processing equipment that Gulab Singh and Co. produce is built so that the entire process of making kurkure is done in the safest possible way. They meet the necessary industry standards and are of the highest quality. We are the top manufacturer, supplier, and exporter of automatic kurkure extruder machine in Ghaziabad, Uttar Pradesh, India.

Fully Automatic Kurkure Production Line

What is a Kurkure production line, and how does it work?

A Kurkure production line is a specialized machine used to manufacture Kurkure snacks. It typically involves processes such as mixing, extrusion, frying, and seasoning. The line operates sequentially to produce Kurkure snacks efficiently.

What are the key components of a Kurkure production line?

A typical Kurkure production line consists of a mixer, extruder, conveyor system, frying unit, seasoning system, and packaging equipment. Each component plays a crucial role in the production process.

What is the production capacity of a Kurkure production line?

The production capacity of a Kurkure production line can vary significantly depending on the model and configuration. Capacities can range from small-scale lines for local production to large-scale, high-capacity lines for mass production.

Is the Kurkure production line customizable for different flavors and shapes?

Yes, Kurkure production lines are often customizable to accommodate various flavors, shapes, and sizes of Kurkure snacks. They can be adjusted to meet specific product requirements.

What are the quality and safety standards for Kurkure production lines?

Kurkure production lines must adhere to stringent quality and safety standards to ensure the production of safe and high-quality snacks. Compliance with relevant food safety regulations is crucial.

What maintenance and servicing requirements are associated with a Kurkure production line?

Regular maintenance is essential to keep the production line in optimal condition. It may involve cleaning, lubrication, and replacement of worn components. Manufacturers often provide maintenance guidelines and service support to ensure smooth operations.