Potato Chips Making Machines Manufacturer

food processing industry, Gulab Singh and Company has emerged as a leading Manufacturer of Potato Chips Making Machines Manufacturer in India. With decades of engineering excellence and a deep understanding of the snacking industry, we specialize in designing, developing, and delivering high-performance potato chips making machines tailored to meet industrial production requirements. Whether you’re a startup setting foot into the snacks business or an established brand looking to expand production capacity, our advanced machinery provides the perfect solution to boost efficiency and maintain consistent product quality.

Gulab Singh and Company, we understand that the demand for potato chips is growing exponentially across domestic and international markets. The crispy, golden chips are a favorite among all age groups, and to meet this demand, snack manufacturers need machines that can deliver on speed, consistency, and hygiene standards. This is where we step in — as a trusted partner in manufacturing and exporting cutting-edge potato chips making machines, helping food businesses scale efficiently and sustainably.

Why Gulab Singh & Company is a Trusted Name in Chips Making Machine Manufacturing

Gulab Singh and Company has carved a niche in the market by adhering to quality, precision, and innovation. As one of the most reliable Potato Chips Making Machine Manufacturers, we believe in constant innovation and customer satisfaction. Each machine is developed under stringent quality controls, ensuring compliance with global food safety and machinery standards.

Key Features of Our Potato Chips Making Machines:

Fully Automatic and Semi-Automatic Options: Catering to diverse production needs, we offer both semi-automatic and fully automatic potato chips making machines that suit small-scale businesses and large industrial setups alike.

High Output with Minimal Waste: Our machines are designed to maximize output while minimizing raw material wastage, helping you increase profitability and reduce operational costs.

Stainless Steel Construction: Built using food-grade stainless steel, our machines ensure hygiene, corrosion resistance, and durability, meeting FSSAI and global safety standards.

Energy Efficient and Low Maintenance: Our advanced chips making machines consume less power and require minimal maintenance, lowering your total cost of ownership over time.

Customizable Configurations: We offer tailor-made solutions based on your production capacity, layout, and operational requirements — including size variations, frying systems, seasoning tumblers, and packaging integrations.

Our Products

| Specification | Details |

|---|---|

| Company Name | Gulab Singh and Company |

| Product Type | Chips Making Machine/Potato Fryer |

| Minimum Order Quantity | 1 Unit |

| Automation Grade | Automatic/Semi-Automatic |

| Material | Stainless Steel (SS-304) |

| Model Numbers | CM-100, CM-200, CM-500 |

| Production Capacity (kg/hr) | 100 kg/hr, 200 kg/hr, 500 kg/hr |

| Power Requirement | 3 Phase Electric Supply |

| Motor Power | 5 HP to 15 HP |

| Voltage Supply | 380V - 415V |

| Machine Dimensions (LxWxH) | Varies by model |

| Components Included | Slicing Machine, Fryer, Oil Filtering System, Cooling Conveyor, Seasoning Unit |

| Features | High efficiency, uniform frying, low oil consumption, easy to operate and maintain, customizable configurations for different chip types |

| Usage/Application | Industrial Snack Production for potato chips and other snacks |

| Sustainability Commitment | Energy-efficient design and compliance with food safety standards |

| Support Services | Installation, training, and after-sales support available |

Potato Chips Production Line: Step-by-Step Automation

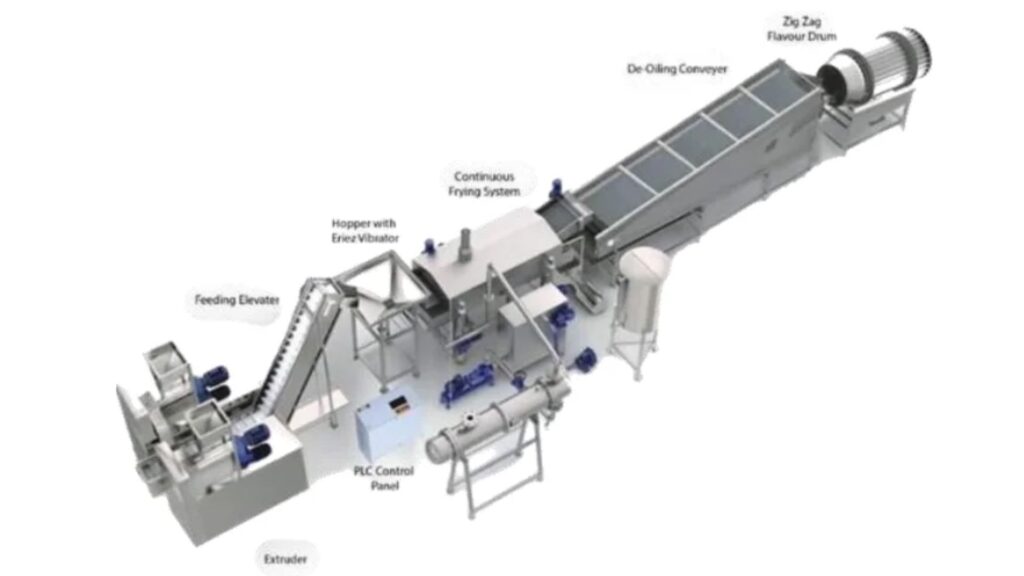

experts in chips production machinery, our automated lines are capable of handling every stage of the potato chips production process. Here’s what a typical Gulab Singh and Company Potato Chips Making Line includes:

Potato Washing and Peeling Machine – Removes dirt, skin, and surface impurities using a high-speed rotating brush and water flow system.

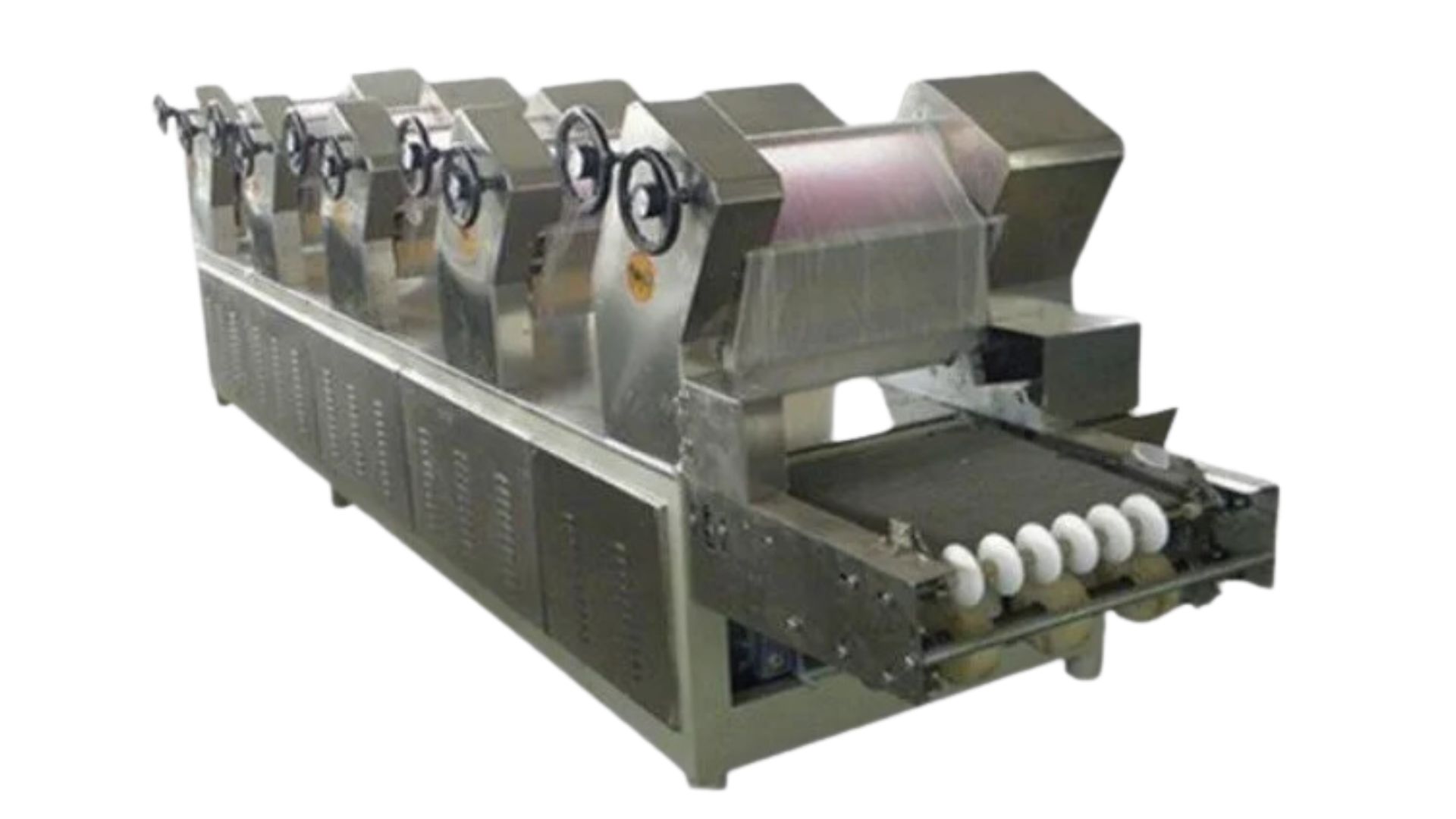

Potato Slicing Machine – Equipped with adjustable blade systems to produce different slice thicknesses and ripple patterns.

Water Starch Removal and Rinsing Unit – Helps in removing excess starch from sliced potatoes, ensuring crispiness after frying.

Blanching Machine – Prepares potato slices for frying, enhances shelf life, and helps in preserving natural color and flavor.

Dehydrator or Dewatering Machine – Removes surface moisture to ensure even frying and reduce oil absorption.

Potato Chips Fryer Machine – Advanced temperature control system for uniform frying, available in batch or continuous models.

Oil Extractor or Oil Separator – Reduces excess oil from chips after frying, promoting health-conscious snacking.

Flavoring and Seasoning Machine – Evenly coats chips with spices, salt, or custom flavor blends for unique taste profiles.

Cooling Conveyor – Ensures chips cool down properly before packaging to maintain crispness.

Packaging Machine (Optional) – Integrates seamlessly with the chips line to automate pouch filling, sealing, and labeling.

Every component in our line is manufactured in-house using high-grade materials and cutting-edge technology, ensuring seamless integration and optimized performance.

Advantages of Choosing Our Potato Chips Making Machines

When you invest in a Gulab Singh & Co. machine, you’re not just buying equipment — you’re partnering with a legacy of trust, innovation, and industry leadership. Here are a few reasons why we’re the top choice among potato chips making machine suppliers in India:

Comprehensive Technical Support: From installation to training and post-sales support, our team is always available to ensure your production line runs smoothly.

In-House R&D and Design Team: We continuously invest in research and development to bring new technologies, improve automation, and reduce processing costs.

Export-Grade Machinery: Our machines are exported to various countries in Asia, Africa, and the Middle East, meeting global standards and CE certifications.

Timely Delivery and After-Sales Service: We understand that time is money, especially in the food production sector. That’s why we ensure quick delivery timelines and proactive maintenance services.

Why Choose Gulab Singh and Company?

Why Choose Gulab Singh and Company?

one of India’s most reputed Potato Chips Making Machine Manufacturers, Gulab Singh and Company stands out in several ways:

Decades of Experience – We bring years of expertise and hands-on knowledge of snack manufacturing, ensuring that every machine we build delivers the performance our clients expect.

State-of-the-Art Manufacturing Facility – machines are designed and built in a modern facility equipped with advanced tools and quality control systems. This guarantees high precision and robust performance.

Client-Centric Approach – We believe in forging long-term relationships with our clients. From consultation and machine installation to after-sales support, we walk with you every step of the way.

Custom Solutions – Every client’s production need is different. We offer fully customized solutions based on production size, floor space, chip type, and budget.

Global Reach – We are not just serving the Indian market but also catering to clients in the Middle East, Africa, Southeast Asia, and other regions, making us a trusted exporter of potato chips machines.

Gulab Singh and Company stands as a symbol of quality, innovation, and trust in the field of potato chips making machine manufacturing. With a wide array of machines catering to every stage of potato chips production, we help businesses boost efficiency, reduce operational costs, and maintain premium product quality. Backed by decades of experience and a customer-first approach, we are committed to supporting snack manufacturers across India and around the globe.

Whether you’re launching a new venture or expanding your existing production capacity, our machines are designed to meet your needs with precision and performance. Choose Gulab Singh and Company as your reliable partner in food processing machinery and take your potato chips business to new heights.